Restoring Nature.

powering sustainable innovation through digital transformation

3D Design can help

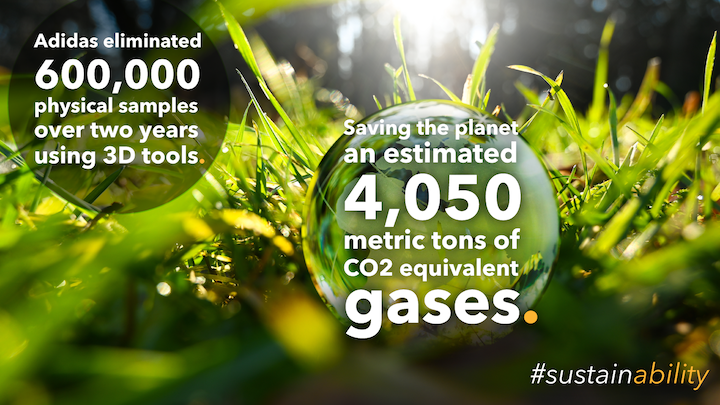

REDUCE PHYSICAL SAMPLE WASTE

DRIVE SUSTAINABILITY GOALS

REDUCE CO2 EQUIVALENT EMISSIONS

ENHANCE YOUR SUSTAINABILITY EFFORTS

By designing your footwear and accessories using 2.5D and 3D tools, you are able to rapidly iterate your design based on colour, texture, and material. This allows you to see photo-realistic product design variations, in real-time, and choose your final design, all without the need to produce unnecessary physical samples. The best news, every physical sample you eliminate enhances your sustainability efforts.

SAVE MONEY, SAVE THE PLANET

The footwear industry generates 700 million metric tons of equivalent CO2 gases per year (6.8 kilograms of CO2 equivalent emissions per shoe). It takes about 1,400 litres of water to create a pair of shoes. And most importantly, these pollutants take thousands of healthy years off of humanity's life expectancy every year. Every physical sample you eliminate helps save the Earth's resources and thousands of healthy years for affected communities.

RESTORE NATURE, EMPOWER IMAGINATION

By designing with 2.5D and 3D tools, you not only dramatically reduce your design times, you create a much more sustainable and resilient supply chain. This means that you are not only able to seamlessly communicate your design intent to your manufacturer, but you are also able to lessen your carbon footprint. It’s a win for your design process and the planet.