Three Must-Haves When Designing for the Store Shelf

Given that it normally takes a consumer less than ten seconds to choose an item on a crowded store shelf (P&G clocks it at 3-7 seconds), consumer packaged goods (CPG) brands are in a tight race for notable superiority against their competitors. On top of that, CPG brands also face stiff competition online. And while most package designing happens in a 2D environment, that is not where they will live. They will live either in the real world or online as a 3D image — with an array of competitors vying for space.

How, then, does a CPG (also known as fast-moving consumer goods, FMCG) brand ensure that the packaging they design today outperform their competitors tomorrow? Foundry has, among its many clients, some of the most innovative brands across many industries. Here are a few tips from our FMCG clients:

Must-Have #1: Shortening your design times to be closer to CPG market demand

In a recent report on the state of the CPG market, Nielson noted that consumers are increasing their demand for more choice. Over sixty percent of buyers say “they like when manufacturers offer new products” and 57% say “they purchased a new product during their last grocery-shopping trip.” This, coupled with the fact that “the vast majority of new product introductions are taken out of distribution before the end of their launch year” means that brands are facing increased pressure to shorten their product lifecycle to keep on the forefront of market demand.

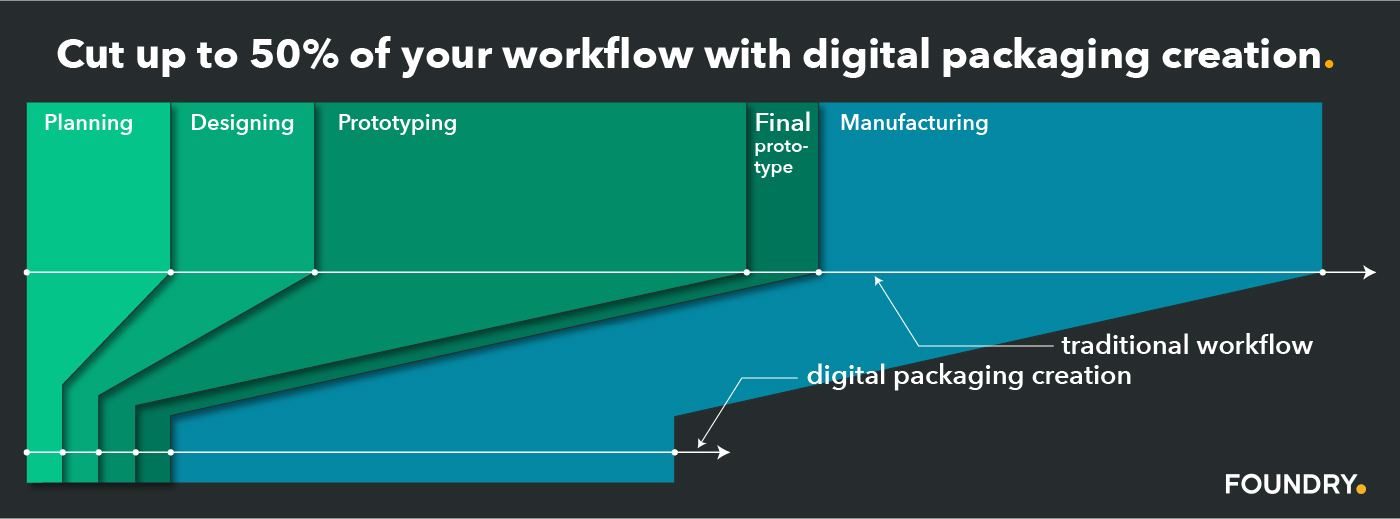

Shortening the product life cycle for the CPG company is critical. One of the best ways to accomplish this is by dramatically reducing your design times. After all, the faster you can get your designs to market, the less time, in advance, you need to predict market demand.

The biggest barrier to reducing design time is the rounds of physical prototypes that you typically need to go through to find your final design. Each physical prototype can take weeks to be made and shipped. If you go through five to ten rounds of revisions that time can really add up. The good news: with virtual prototyping, what normally takes weeks or months can now be accomplished in hours or days. And not only that, by virtually iterating on your packaging design, you reduce the waste associated with physical prototypes.

Must-Have #2: Designing with your competitors in mind to gain notable superiority

The truth is, your packaging designs don’t live in a vacuum. They live in a crowded competitive landscape, contending for every set of eyes. If you aren’t incorporating that into your design thinking, you are likely missing market share.

How do you make sure that your packaging will be notably superior when stacked against your competitors? Put simply: You must see your designs in the context of the store shelf or e-commerce website. If you don’t have a photo-realistic 3D twin of your packaging, placed on the store shelf or Amazon page, you’ll never know how it will perform in the wild. Consider the image below. On the left is a CAD representation of the product. On the right is a 3D twin of the packaging, this time placed on a store shelf

With CAD software (left), you get a sense of the product’s dimensions and overall appearance:

- Is the label properly placed?

- Is the cap proportional to the body?

- Is the overall structure of the packaging as design intended?

But look at what the 3D render tells you (right). Yes, it tells you everything the CAD render does, but it also informs you on:

- How does the retailer’s light play with the overall packaging design?

- How does light interact with the label design?

- Does the white bottle color subtly attract more attention compared to the competitors' color choice?

- How does the gold enhance/detract from the design in comparison to the other bottles on the shelf?

With 3D twins placed in-context, not only will you be able to ask these questions in the design stage, you will be able to make changes, on-the-fly. This means you will be able to test your design in FMOT conditions without the wait of a physical prototype.

Must-Have #3: Conducting consumer research virtually to get results faster

Consumer studies are vital in understanding if your packaging design will perform as expected while on the store shelf. But setting up a physical consumer study can be time consuming. Now-a-days, however, there is no end of software to help you do this virtually. The problem is, does that software offer a true-to-life representation of your packaging designs for the shopper to compare against your competitors? And if it does, are you able to rapidly iterate on that design so that you can get consumer reaction in real-time

If the answer is no on either account, then you are likely missing out on the needed information to make the most informed decision. Take, as an example, the below animation:

Here we see the same body wash as in the example above, but this time both the cap and label are being iterated on, while in context. Here, you can see in real-time how those changes look in relation to the competitors on either side of the shelf. More importantly, if you are conducting a virtual consumer study, the shoppers will be able to see the changes and give you their feedback instantly.

It’s this kind of information that is powerful and will allow you to make the most of your consumer studies.

Final Thoughts

Given these three must haves for ensuring notable superiority in FMOT scenarios, you need a way to rapidly iterate, in real-time, with virtual prototypes and use those same virtual products to conduct consumer research in both online and virtual retail environments. In this way you can see how your packaging designs will interact with your competitors where it is needed most — in real-time and in-context. The good news: You can with Foundy’s products.

With Colorway and Modo, you can:

- Iterate on your designs with photo-realistic renders.

- Place virtual prototypes in any context imaginable (online or retailer’s shelf).

- Conduct consumer studies and incorporate feedback in real-time.

- Seamlessly work with 2D and 3D designers to find your final design, faster.

With Colorway and Modo, you can truly see what your final design will look like before it rolls off the production line. What’s more, once it comes off the line, you can be confident that it will be notably superior when it is placed on the shelf.

Editor's Note: Portions of the blog post have been taken and modified from our White Paper: Mastering the First Moment of Truth. (to download the full white paper, please follow the link)